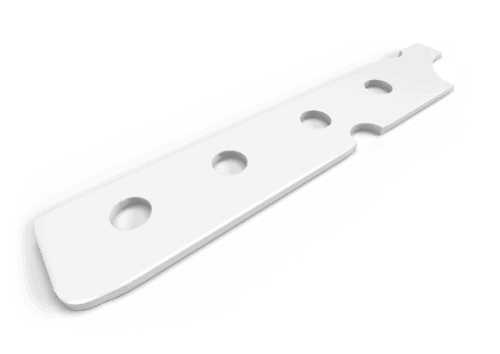

Plastic stamping is a manufacturing process that enables the creation of very thin parts. Typically, this process utilizes a set of dies and a punch press. The press is available in both conventional and high speed options, with varying tonnages depending on the equipment. This machinery is able to punch a shape from a non-metallic substance such as extruded plastic. Manufacturers can utilize plastic stamping to create an array of flat shapes, including gaskets and washers.

What Dies Are Used in Plastic Stamping?

Dies are highly versatile, with applications across a wide range of industries. The plastic stamping process will most commonly utilize a compound die, which consists of two separate dies. One cuts the outside diameter of the workpiece, while the other punches the interior. After the plastic stamping is complete, high pressurized air will blow away any excess material. The benefit of compound dies is that they enable all stamping to be completed in a single stroke, rather than two separate strokes.

New Process Fibre differs from many other stamping companies, as we specialize in stamping high performance non-metallic materials. We offer an array of stamping solutions, from single stroke compound dies to high-speed progressive dies. This enables us to meet the needs of every customer looking to manufacture high quality non-metallic products.

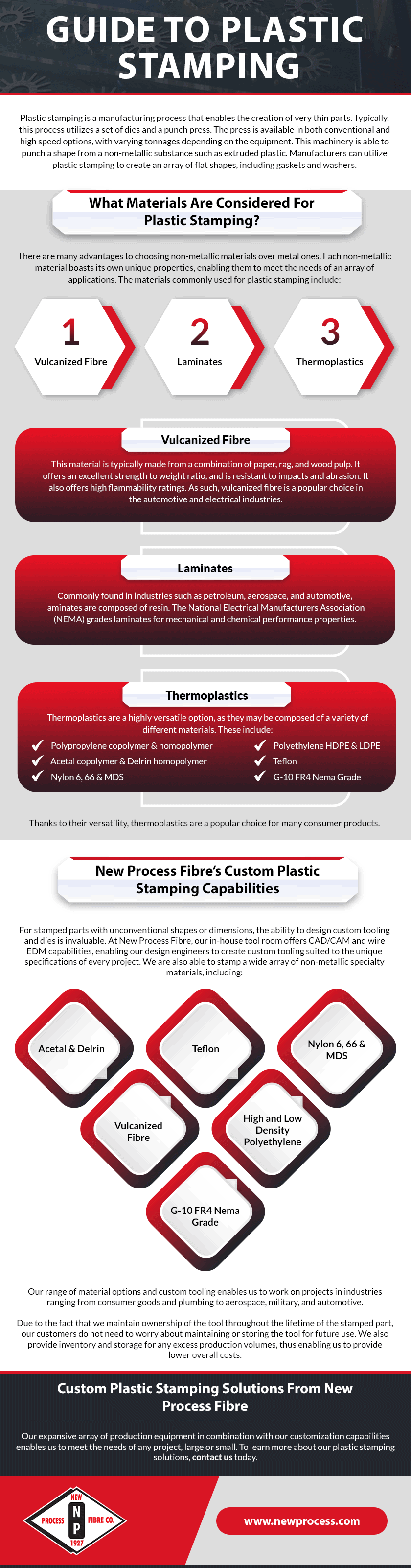

What Materials Are Considered for Plastic Stamping?

There are many advantages to choosing non-metallic materials over metal ones. Each non-metallic material boasts its own unique properties, enabling them to meet the needs of an array of applications. The materials commonly used for plastic stamping include:

- Vulcanized fibre

- Laminates

- Thermoplastics

Vulcanized Fibre

This material is typically made from a combination of paper, rag, and wood pulp. It offers an excellent strength to weight ratio, and is resistant to impacts and abrasion. It also offers high flammability ratings. As such, vulcanized fibre is a popular choice in the automotive and electrical industries.

Laminates

Commonly found in industries such as petroleum, aerospace, and automotive, laminates are composed of resin. The National Electrical Manufacturers Association (NEMA) grades laminates for mechanical and chemical performance properties.

Thermoplastics

Thermoplastics are a highly versatile option, as they may be composed of a variety of different materials. These include:

- Polypropylene copolymer and homopolymer

- Polyethylene HDPE & LDPE

- Teflon

- Acetal copolymer & Delrin homopolymer

- Nylon 6, 66 & MDS

- G-10 FR4 Nema Grade

Thanks to their versatility, thermoplastics are a popular choice for many consumer products.

New Process Fibre’s Custom Plastic Stamping Capabilities

For stamped parts with unconventional shapes or dimensions, the ability to design custom tooling and dies is invaluable. At New Process Fibre, our in-house tool room offers CAD/CAM and wire EDM capabilities, enabling our design engineers to create custom tooling suited to the unique specifications of every project. We are also able to stamp a wide array of non-metallic specialty materials, including:

- Acetal & Delrin

- Teflon

- Nylon 6,66 & MDS

- Vulcanized fibre

- High and low density polyethylene

- G-10 FR4 Nema Grade

Our range of material options and custom tooling enables us to work on projects in industries ranging from consumer goods and plumbing to aerospace, military, and automotive.

Due to the fact that we maintain ownership of the tool throughout the lifetime of the stamped part, our customers do not need to worry about maintaining or storing the tool for future use. We also provide inventory and storage for any excess production volumes, thus enabling us to provide lower overall costs.

Custom Plastic Stamping Solutions From New Process Fibre

Since 1927, New Process Fibre has been dedicated to innovation and growth. Our operation began from a desire to design a more efficient and cost-effective process for creating vulcanized fibre from cotton paper. We have continued this trend of innovation for nearly a century, performing all our manufacturing in-house to provide our customers with the highest quality non-metallic stamped parts. Our expansive array of production equipment in combination with our customization capabilities enables us to meet the needs of any project, large or small. To learn more about our plastic stamping solutions, contact us today.