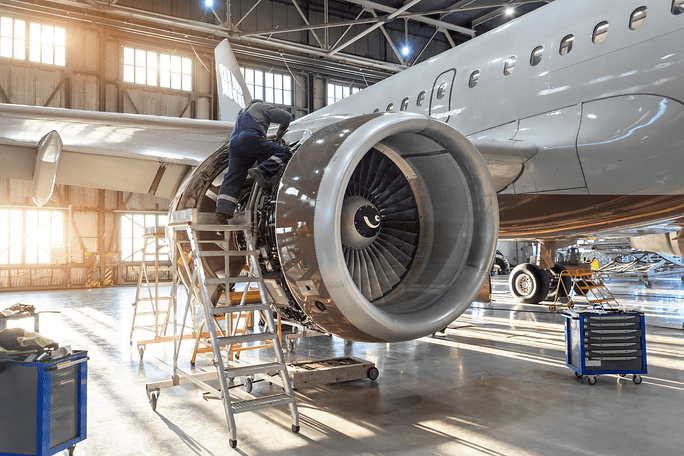

Aerospace & Military Industries

Nylon and polypropylene are both ideal for aerospace and military washers because of their light weight, durability, and resistance to abrasion, heat, and chemicals.

Appliances

Many manufacturers opt for plastic washers due to their chemical resistance and thermal insulation, allowing plastic washers to withstand electricity, corrosive materials, and high temperatures.

Automotive

Plastic washers are the automotive workhorse — they are often found in engine compartments, where they are subjected to extreme temperatures, chemical fluids, and tremendous workloads.

Electronics

Plastic washers are a popular choice in the electronics industry because they are anti-magnetic, non-sparking, and capable of withstanding high electrical volts.

HVAC

Customers seek increasingly smart HVAC systems that facilitate more optimization, automation, and remote connectivity and control.

Marine

For many marine industry applications, Nylon is an ideal material because of its corrosion and wear resistance and long life.

Medical

By using the right types of washers, medical products benefit from effective sterilization and longer service life, creating a safer environment and saving medical facilities money on maintenance.

Plumbing

New Process Fibre produces high-performance plastic plumbing washers that can provide cost and wear resistance benefits over their metal counterparts.

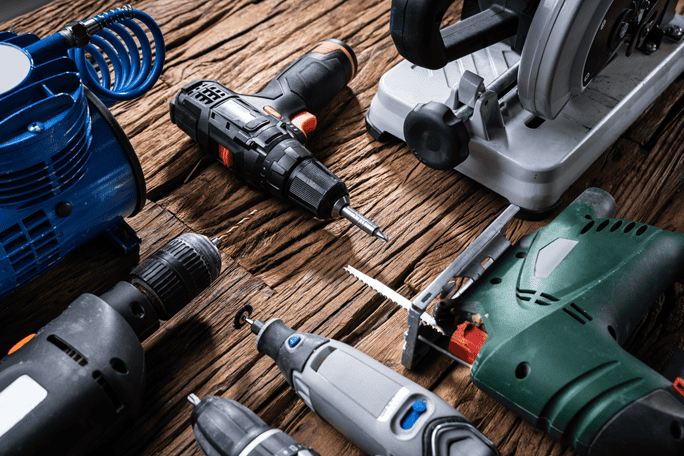

Power Tools

Power tool manufacturers can’t compromise on quality and durability. Washers, gaskets, and seals are a critical part of maintaining proper tool operation and longevity.

Sporting Goods

Non-metallic components are used in sporting goods, fitness and exercise equipment, outdoor gear, and recreational equipment to maintain high-performance in harsh environmental conditions.