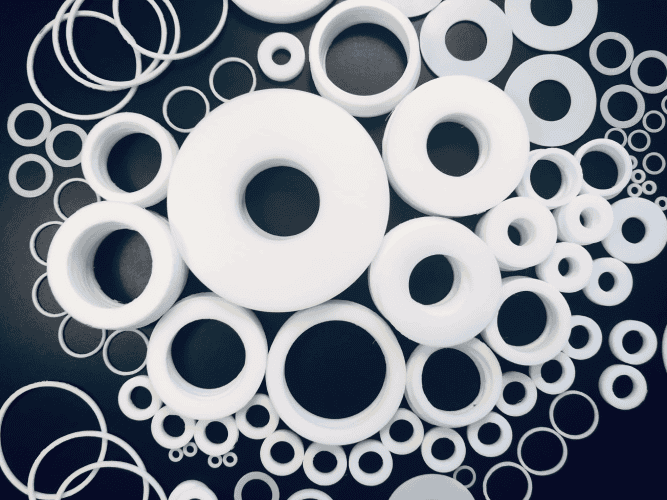

Specialty Washers

Two varieties of specialty washers are virgin PTFE washers and PTFE sealing washers. Virgin Teflon™, which is PTFE in its unfilled state, offers all of the positive attributes of reprocessed Teflon™ but to a higher degree. Due to its 100% purity, virgin PTFE has excellent thermal stability, very low levels of friction, and high electrical insulation capabilities. Recycled PTFE is more affordable but can no longer offer the same degree of protection and long-lasting functionality.

Because of how inert virgin PTFE is, it’s ideal for use in scientific equipment, food processing systems, and precision electronics that can’t afford the variability of reprocessed PTFE. At New Process Fibre, our production team uses only virgin Teflon™ resin to produce Teflon™ washers of the highest possible quality.

Then there are PTFE sealing washers. General washers provide a buffer between mating components to mitigate abrasion, scratches, and other physical damage. Sealing gaskets offer additional functionality by creating a leak-tight seal that, due to PTFE’s inertness again, is less likely to chemically degrade. In addition to their chemical resistance, PTFE sealing washers deliver reduced friction and the ability to retain sealing capabilities at high temperatures, benefits that rubber washers can’t always achieve.

Some common use cases for PTFE sealing washers are electrical and electronic assemblies, chemical processing equipment, pharmaceutical production, and food processing applications. Such projects often involve highly reactive chemicals and a wide range of temperatures throughout processing, and facilities need PTFE sealing washers they can rely on for long-term performance.